Electric Vehicle Battery Pack Encapsulation Kit

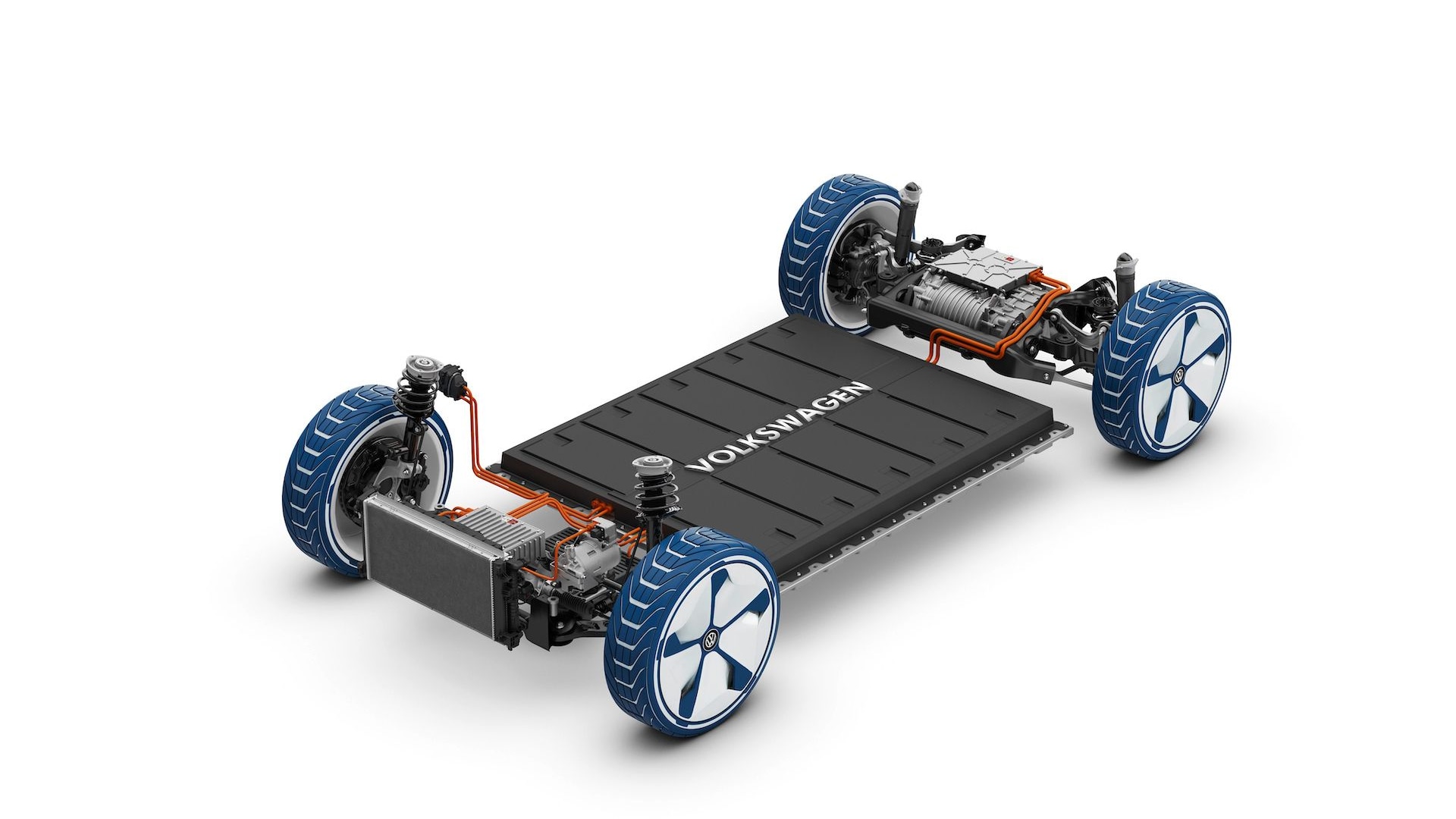

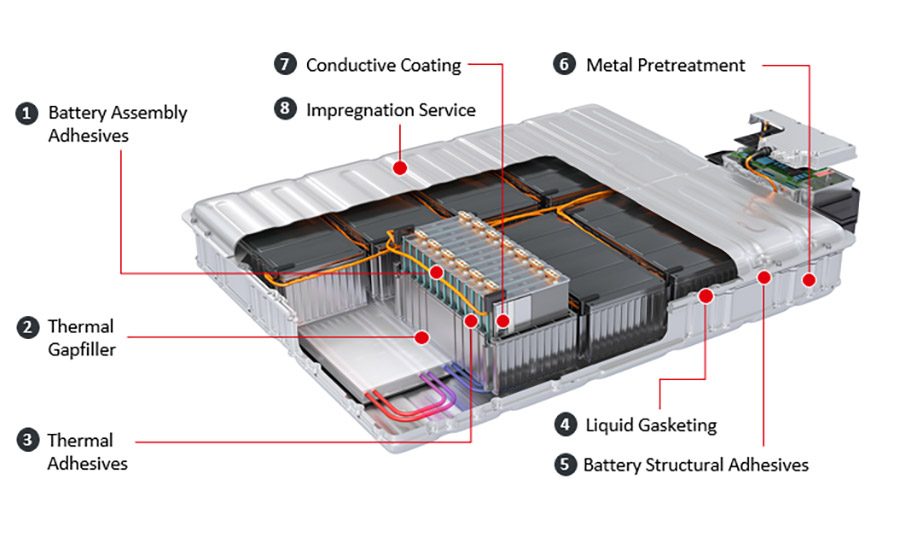

Electric Vehicle Battery Pack Encapsulation Kit. Patvin solutions for battery encapsulation. Adhesive technology plays a vital role in the assembly and performance of electric vehicle battery packs.

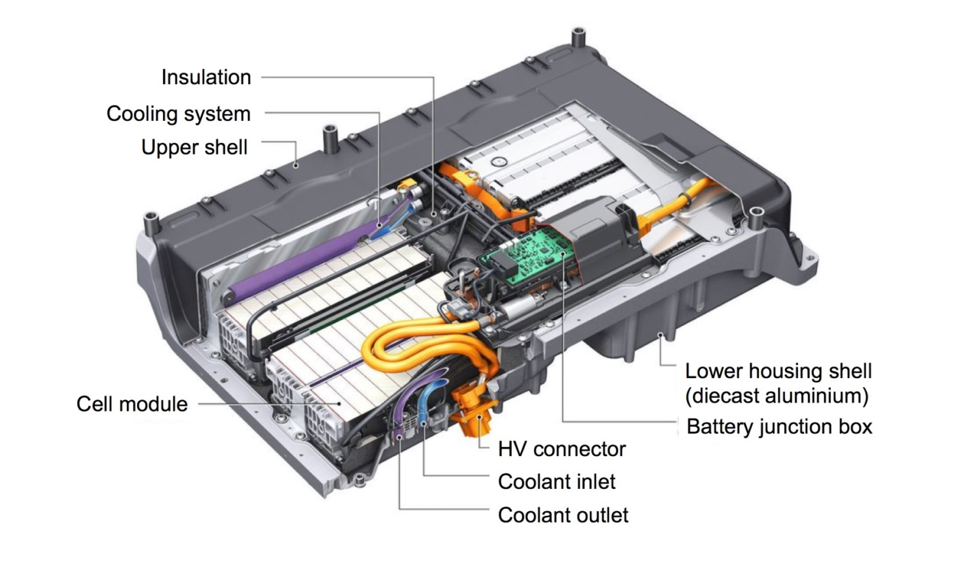

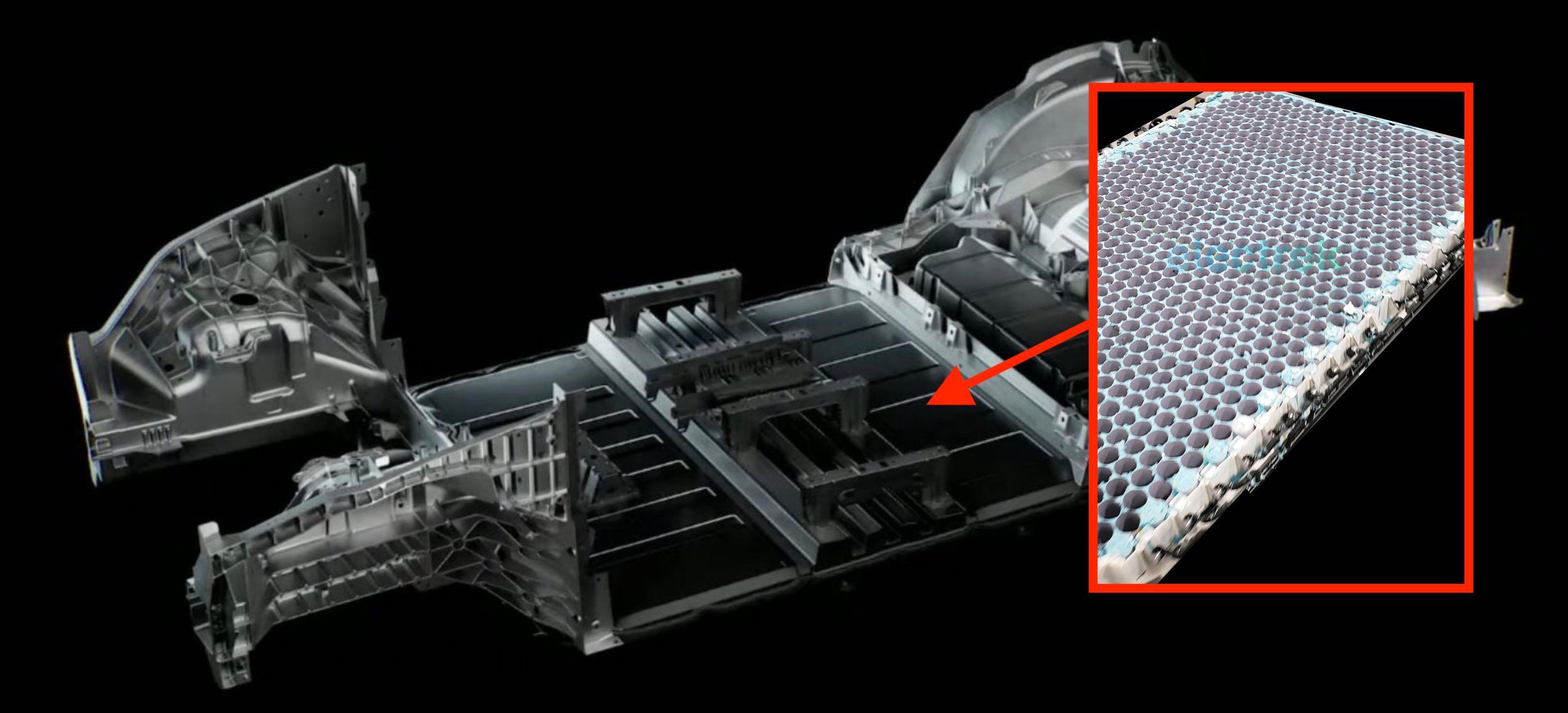

During the actual operation of electric vehicle, the battery packs and its enclosure is subjected to harsh environmental conditions such as the external vibrations. The ev battery cell is the most basic and smallest packaged unit in the battery.

Therefore, It Is Necessary To Predict Battery Heat Generation.

Bonding solutions for electric vehicle battery cells.

Solutions For Ev Battery Manufacturers.

Electromobility has gained significance over recent years in an attempt to reduce greenhouse gas emissions which contribute to climate change.

The Vast Majority Of Vehicles On The Road Today Are Powered By Traditional Fuels, But Make No Mistake, Electric Vehicles (Evs) Are Making Serious Inroads.

Images References :

Source: mypoisonedapple.blogspot.com

Source: mypoisonedapple.blogspot.com

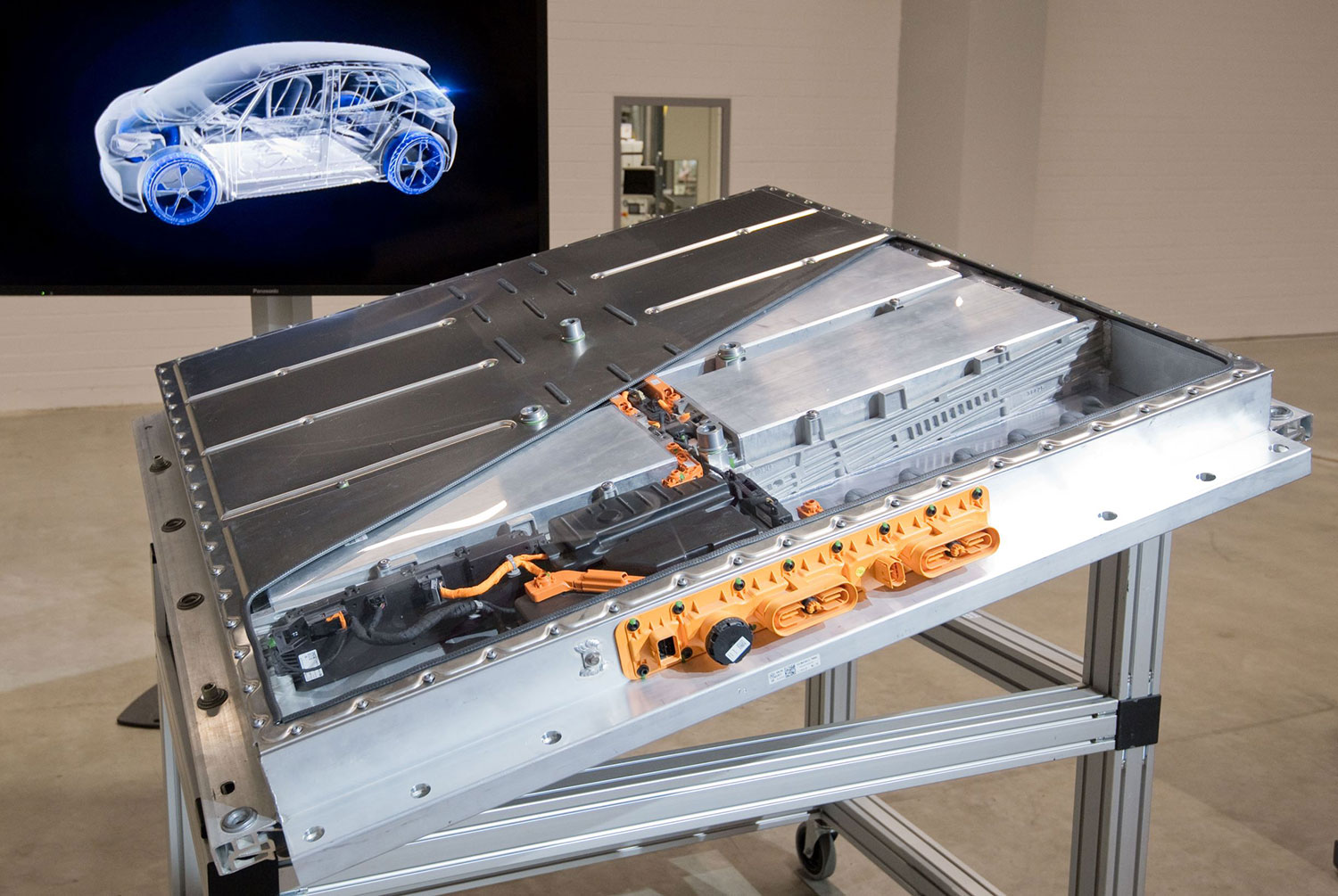

Electric Vehicle Battery Pack Battery Pack Kwh Built System Ev 144v 96v, Patvin solutions for battery encapsulation. Bonding solutions for electric vehicle battery cells.

Source: us.misumi-ec.com

Source: us.misumi-ec.com

How Electric Vehicle Battery Packs are Manufactured MISUMI Mech Lab Blog, We provide proven safety, higher effectiveness, longer and more effective performance. Adhesive technology plays a vital role in the assembly and performance of electric vehicle battery packs.

Source: mypoisonedapple.blogspot.com

Source: mypoisonedapple.blogspot.com

Electric Vehicle Battery Pack Battery Pack Kwh Built System Ev 144v 96v, Patvin solutions for battery encapsulation. From ensuring structural integrity to managing heat and.

Source: www.inceptivemind.com

Source: www.inceptivemind.com

Robotic disassembly system makes EV battery recycling safer, faster, Therefore, it is necessary to predict battery heat generation. Secondary insulation applications in electric motors include three types of encapsulation:

Source: www.adhesivesmag.com

Source: www.adhesivesmag.com

Henkel to Debut Electric Vehicle Battery Material Solutions at the, Heat is generated when the battery pack is being used. Ev battery cells come in a variety of cell chemistries, with the most popular.

Source: cyan-tec.com

Source: cyan-tec.com

Laser System Integration for Electric Vehicle Battery Pack CyanTec, Climatization of batteries to the optimal operating temperatures. From ensuring structural integrity to managing heat and.

Source: www.solutions.covestro.com

Source: www.solutions.covestro.com

EV battery pack design Covestro AG, Farasis does not go into any more detail at this point. Adhesive technology plays a vital role in the assembly and performance of electric vehicle battery packs.

Source: kimsen.vn

Source: kimsen.vn

Aluminium Extrusions Are Winning The Race For Battery Enclosure In EVs, The company has also developed a range of materials for the ev battery cell itself. Material and the proper mix.

Source: ar.inspiredpencil.com

Source: ar.inspiredpencil.com

Electric Car Battery Pack, Foam encapsulation can add structure and rigidity to the battery pack by holding cells in place to protect them from shocks or vibrations. Its shokless encapsulation foam and elastomer systems help to create potting.

Source: electrek.co

Source: electrek.co

First look at Tesla's new structural battery pack Electrek, Adhesive technology plays a vital role in the assembly and performance of electric vehicle battery packs. During the actual operation of electric vehicle, the battery packs and its enclosure is subjected to harsh environmental conditions such as the external vibrations.

Material And The Proper Mix.

The packaging and packing from individual cells in the shape of.

The Automotive Industry Is Moving To Electric Vehicles, And Ev Batteries Need To Be Safe, High Performing And Lightweight.

Foam encapsulation can add structure and rigidity to the battery pack by holding cells in place to protect them from shocks or vibrations.